Back in 2011 I created eventcountdown.com. It had a snazzy downloadable, PerfectTablePlan-branded countdown clock for Windows and web-based countdown clock with ads for PerfectTablePlan. Both free. The idea was people searching for countdown clocks for events (such as their wedding) would find the site via Google, find out about PerfectTablePlan and a certain percentage would then buy my event seating planner software.

I paid other people to create the Windows and web versions of the countdown clock. The web-based clock was updated from time to time to add pre-built countdowns for events like superbowl, the olympics, christmas, thanksgiving etc. And I fielded the occasional support emails related to the Windows countdown clock.

This is the total traffic to the site from 2011 to 2023:

The peaks are mostly due to superbowl. The site got 38k hits in a single day just before superbowl 2019! The free Windows countdown clock also drew quite a lot of traffic. In total the site got some 1.7 million page views over 12 years. Only a small percentage of these visitors clicked through to PerfectTablePlan.com, but still a useful number. Perhaps some people were also prompted to investigate PerfectTablePlan by the branding on the downloadable clock. The site might have also had some SEO benefits for PerfectTablePlan.com. Who knows.

The eventcountdown.com website is now gone (the domain redirects to PerfectTablePlan.com). It didn’t seem worth the effort to keep adding events to the web countdown clock with the traffic now so low. Also both the website and windows clock were looking dated. But I think it was a worthwhile investment of my time and money.

I have also created various other contents pages and mini-sites over the years: articles on table planning, font collections, free clipart, place card templates etc. You can see similar trajectories for some of those.

The traffic seems to reach a peak after 3-7 years and then slowly decay away. Although I have shown them with the same vertical scale here, some generated a lot more traffic than others.

I did some basic on-page SEO for these content pages. For example, looking at Adwords keyword data to choose the page title and H1. But nothing beyond that. No paid promotion or backlink building campaigns.

I tried paying people to write articles related to events. But none of these ever generated any worthwhile traffic. Google could somehow smell the insincerity.

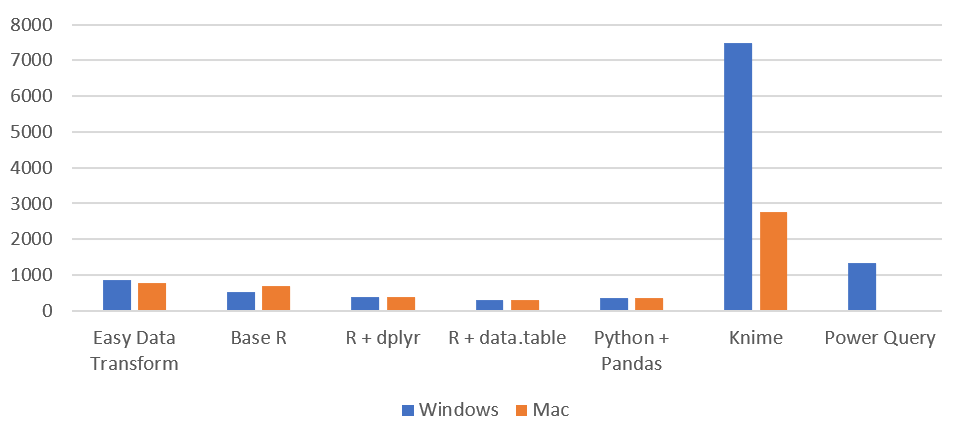

For my data cleaning software product I have been concentrating on ‘how to’ pages and supporting videos aimed at specific topics. These are intended to both help existing customers and to attract new traffic. For example, how to clean data. I have also been posting these videos on the Easy Data Transform YouTube channel. The numbers of hits monthly on the Youtube videos are relatively low, but they are quite targeted and hopefully will be generating traffic for years to come.

So content marketing take-aways based on my experience are:

- Free content can be a useful way to bring free traffic to your website.

- The amount of traffic you get is quite hit and miss. Some content has generated a lot more traffic than expected, some a lot less.

- The content needs to be well targeted if you want to have any chance of converting it to sales.

- Google will grow bored of it eventually. You might be able to increase the longevity by updating the content. I’ve not been very diligent with this, but even neglected content pages can generate useful traffic over 10+ year lifespan.